High Efficiency Ceramic Liner Jet Mill for Inorganic Fertilizer Production Line

The rapid development of livestock and poultry farming produces a lot of excrement and sewage. The harmful elements of these fouling are too high to be processed by traditional returning way. For this situation, our company has developed the organic fertilizer production line which use high efficient solid-liquid rotten aseptic deodorization technology as the core, and the whole production equipment process includes: high efficient excrement, raw material mixing, granule processing, drying and packing.

Introduction:

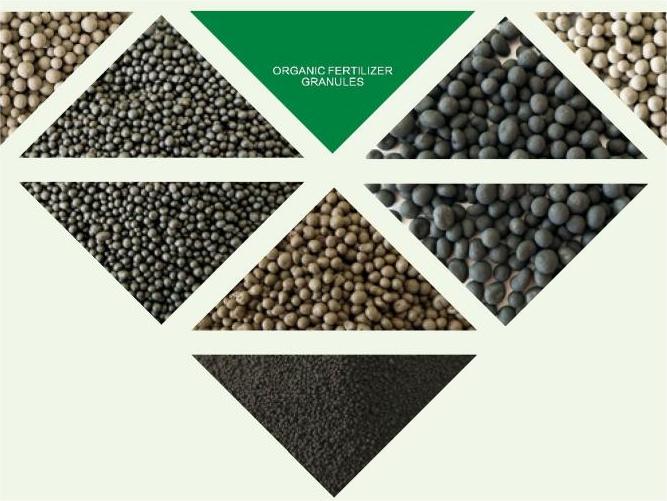

The products of organic fertilizer production line are made of fresh chicken and pig manure, without any chemical composition. The digestive ability chickens and pigs is poor, so they can only consume 25% of nutrients, then another 75% in feed will be excreted with faeces, so that the dry product will contain nitrogen, phosphorus, potassium, organic matter, amino acid, protein and other ingredients. In the urine and manure of livestock, a year of excrement urine of a pig. It contains 11% of organic matter, 12% of organic matter, 0.45% of nitrogen, 0.19% of phosphorous oxide, 0.6% of potassium oxide, and is enough fertilizer for the fertilizer of whole year. These organic fertilizer is rich in nitrogen, phosphorus, potassium and other nutrients, with more than 6% content and more than 35% organic matter content, all of these is above national standard.

Raw Materials:

- •Agricultural waste: straw, dregs of beans, cotton dregs, rice bran, etc.•Animal manure: mixture of poultry litter and animal waste, such as the wastes of slaughterhouse, fish market, urine and dung of cattle, pigs, sheep, chicken, ducks, geese, goat, etc.•Industrial waste: wine lees, vinegar residue, manioc waste, sugar scum, furfural residue, etc.•Home scrap: food waste, the roots and leaves of vegetables, etc.•Sludge: the sludge of the river, sewer, etc.

Related products:

- Compost turner

• Automatic batching machine

• Horizontal mixer

• New type orgainc fertilizer granulator

• Dryer&Cooler

• Sievingmachine

• Coating machine

• Packing machine

• Chain crusher

• Belt conveyor

Detail

|  |

|  |

|  |

Elevate your organic fertilizer production line with our high-tech ceramic liner jet mill, meticulously crafted to process fresh chicken and pig manure without the use of any harmful chemicals. With a focus on efficiency and quality, our innovative technology ensures optimal results for your inorganic fertilizer production needs. Trust GETC for all your equipment technology solutions.