High Efficiency Jet Mill and High Speed Blender Supplier - GETC

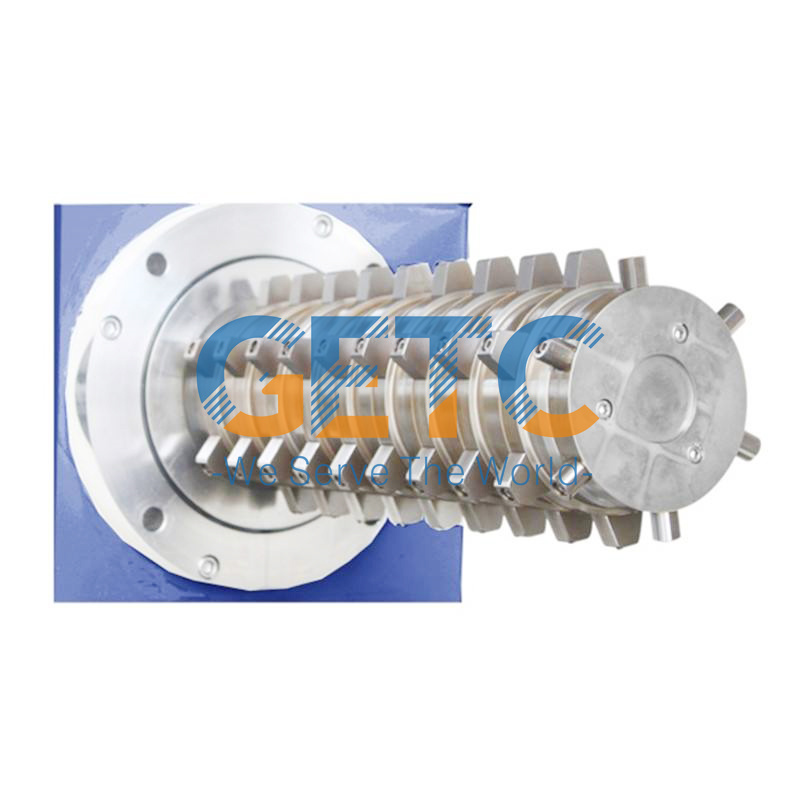

The delivery pump circulates the materials in the tank and the materials in the grinding chamber. The main shaft in the grinding chamber is equipped with many pins with high anti-abrasiveness and hardness. The pins drive the grinding medium inside the grinding chamber to do irregular movements in all direction to put the materials under the action of constant collision and friction. At same time, the materials are separated from the grinding medium by the sieve and keep circulating from the tank to the grinding chamber to obtain smaller particle size, narrower particle size range.

Looking for a reliable supplier and manufacturer of high efficiency jet mills and high speed blenders? Look no further than GETC. Our cutting-edge equipment is designed to provide unparalleled performance and efficiency, making us the top choice for industries requiring precision and quality. With a novel structure and high stability, our products guarantee superior results every time.Features:

- •Novel structure, high stability.

•Strengthened frame with reasonable structure, steady operation and easy maintenance. Besides, nicer appearance with full of modern sense.

• The main parts an out-sourced parts are international renowned brands with higher stability and longer service life.Easy to clean, strong durability.

• Unique tri-pole mechanism design makes it easy to open for cleaning and replacing grinding chambers.

• The grinding chamber, made of high wear-resistance alloy steel, is treated specially to realize higher wear resistance and longer service life. In addition, Burgmann Dual-end Mechanical Seal with self-lubricating system contributes directly to higher reliability and durability.Safe monitor, stable product.

• The machine is with triple cooling: internal, external, and end face, which ensures the grinding heat exchanged out in time.

• The water temperature, material temperature, material pressure,water pressure, air pressure and other real-time monitoring and protection system ensure proper operation of the machine.Full specification, can be customized.

• Specifications ranges from 5L to 50L, which can be customized to be Ex-proof type.

- Application:

Suitable for printing ink, solvent ink, water-based ink, automobile paint, industrial coating, pigments, color paste, and nanometer materials.

- SPEC:

Model | Volume (L) | Dimension (L×W×H) (mm) | Motor (kw) | Feeding Speed (L/min) | Capacity (kg/h) |

WMZ-15 | 15 | 1210×765×1420 | 15 | 0-17 | 50-500 |

WMZ-25 | 25 | 1370×800×1600 | 22 | 0-17 | 70-700 |

WMZ-30 | 30 | 1580×850×1650 | 22 | 0-17 | 80-800 |

WMZ-50 | 50 | 1920×1050×1700 | 30 | 0-40 | 100-1000 |

Detail

|  |

|  |  |

At GETC, we understand the importance of quality and efficiency in milling operations. That's why our High Efficiency Jet Mill and High Speed Blender are carefully crafted to meet the highest standards in the industry. Whether you need to process high viscous bead mill materials or achieve fine particle size reduction, our products are engineered to deliver exceptional results consistently. Experience the ultimate in milling technology with GETC. Trust us to be your reliable partner in achieving outstanding results with our High Efficiency Jet Mill and High Speed Blender. Choose excellence, choose GETC.