High Quality Mixer Supplier - Changzhou General Equipment Technology Co., Ltd.

-

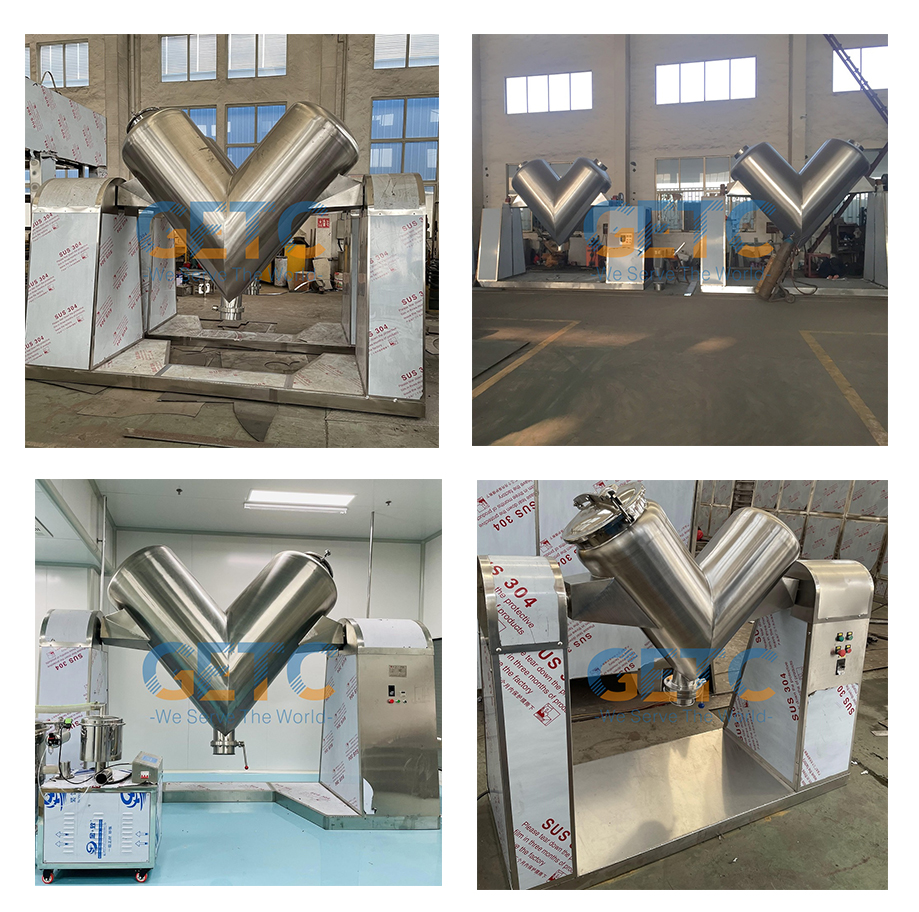

The structure of this machine is unique. Its mixing efficiency is high and no dead corner. It is made of stainless steel . its inner and outer wall is processed through polishing. Its apperance is beauty.

Its mixing is uniform. Its scope of application is wide. The forced stirrer can also be equipped in order to meet the requirements of raw materials that contain fine powder, cake and certain moisture as request.

Introduction:

The structure of this machine is unique. Its mixing efficiency is high and no dead corner. It is made of stainless steel . its inner and outer wall is processed through polishing. Its apperance is beauty.

Its mixing is uniform. Its scope of application is wide. The forced stirrer can also be equipped in order to meet the requirements of raw materials that contain fine powder, cake and certain moisture as request.

Feature:

- One end of the machine is equipped with a motor and a reducer, and the motor power is transmitted to the reducer through the belt, and the reducer is then transmitted to the V-barrel through the coupling. The V-shaped barrel is continuously operated, and the materials in the barrel are driven to mix up, down, left and right in the barrel.

Application:

It is suitable for the mixing of powder and granules with good material fluidity and small difference in physical properties, as well as the mixing of materials with low mixing degree requirements and short mixing time, because the material flow in the V-type mixing container is stable and will not destroy the original shape of the material, so the V-type mixer is also suitable for the mixing of fragile and easily worn granular materials, or the mixing of finer powder, lumps and materials containing a certain amount of water, which is widely used in pharmaceutical, chemical, food and other industries.

Specification:

Model | V-0.18 | V-0.3 | V-0.5 | V-1.0 | V-1.5 | V-2.0 | V-2.5 | V-3.0 |

Capacity (kg/batch) | 72 | 90 | 150 | 300 | 450 | 600 | 800 | 900 |

Mixing time (min) | 4-8 | 6-10 | 6-10 | 6-10 | 6-10 | 6-10 | 6-10 | 8-12 |

Volume (m³) | 0.18 | 0.3 | 0.5 | 1.0 | 1.5 | 2.0 | 2.5 | 3.0 |

Stirring speed (rpm) | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 10 |

Power of motor (kw) | 1.1 | 1.1 | 1.5 | 3 | 4 | 5.5 | 7.5 | 7.5 |

Weight (kg) | 280 | 320 | 550 | 950 | 1020 | 1600 | 2040 | 2300 |

Detail

| |