High Quality Spiral Jet Mill Supplier for Pharmaceuticals/ Pesticides - GETC

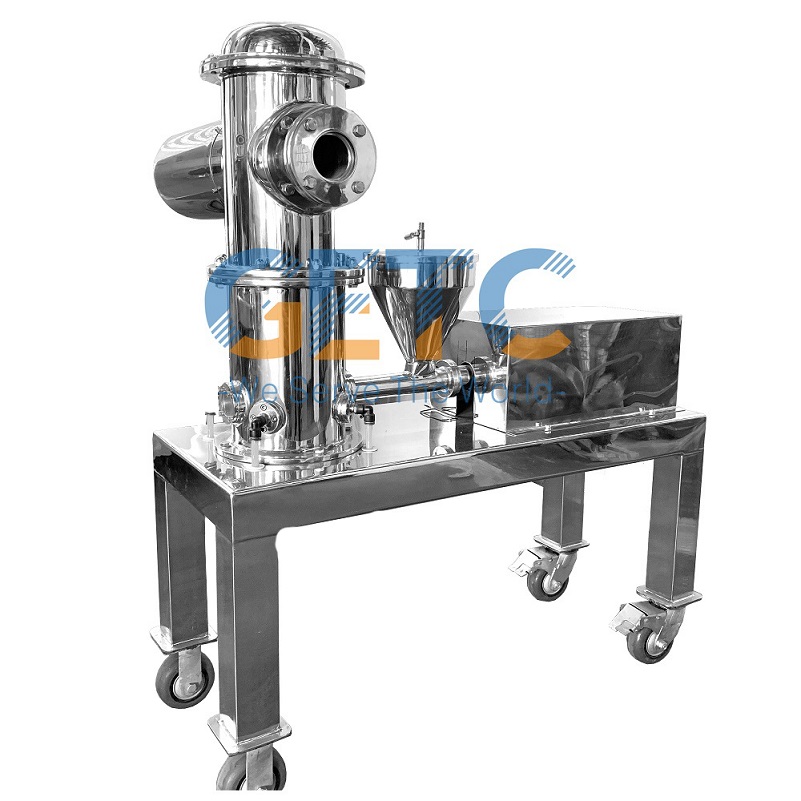

The Fluid bed Jet Mill from Changzhou General Equipment Technology Co., Ltd. offers top-notch performance in grinding dry powders to micron averages. With a horizontal classifier wheel, laboratory to production models, and rapid cleaning capabilities, this Micronizer is ideal for pharmaceutical and pesticide applications. Enjoy low production loss, low noise levels, and precise classification with the Variable speed classifier wheel and Ceramic, PU lining. Trust in our advanced design and total system automation for the highest quality manufactured product. Experience the advantages of a top supplier and manufacturer in fluid bed jet milling technology.

At GETC, we pride ourselves on providing top-of-the-line Spiral Jet Mills that deliver exceptional performance in pharmaceutical and pesticide industries. Our innovative design and precision engineering ensure that particles are effectively entrained in the air or inert gas stream, resulting in superior product quality and efficiency. With years of experience and expertise in the field, we are dedicated to meeting the unique requirements of our customers and exceeding expectations. Choose GETC as your trusted Spiral Jet Mill supplier and experience the difference in milling technology.

DCF series jet mill is a fluid bed jet mill which features opposed grinding nozzles and a dynamic classifier. Air or inert gas at elevated pressure is injected through specially designed nozzles directly into the grinding chamber of the mill, creating a sonic or supersonic grinding stream. Raw feed is automatically introduced to the mill chamber by an interlocked feed control system.

- Brief Introduction:

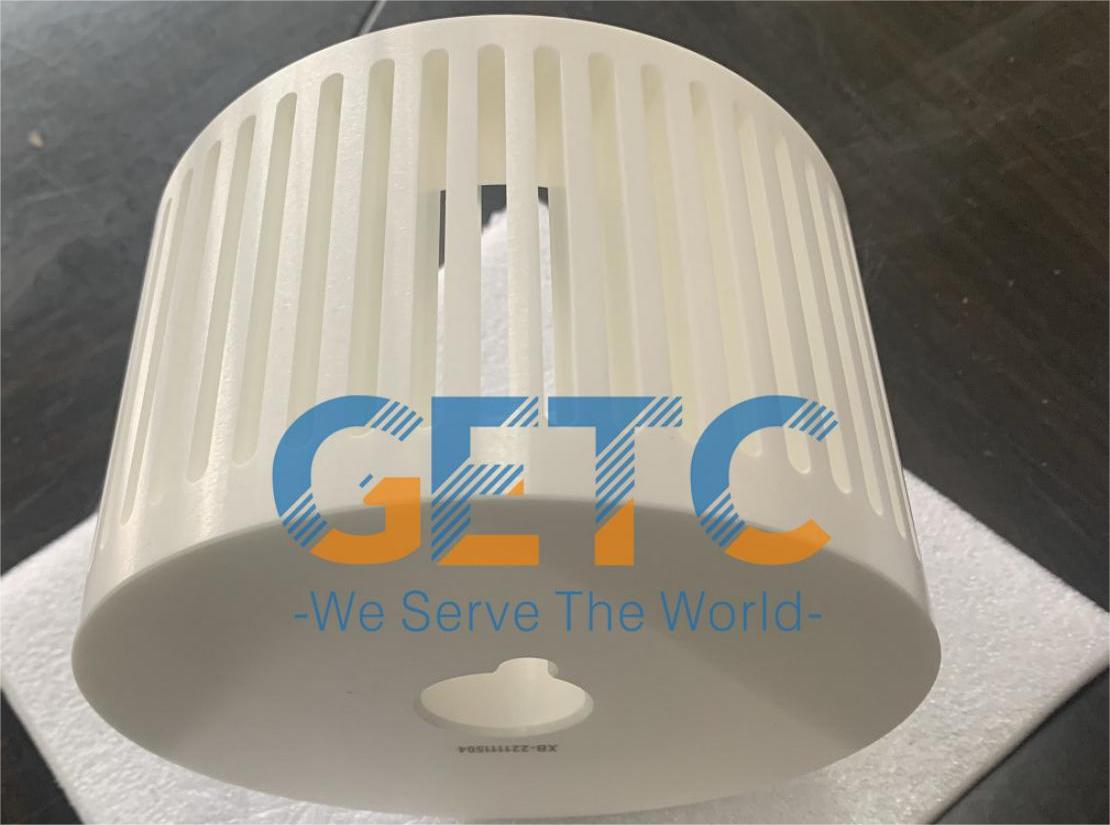

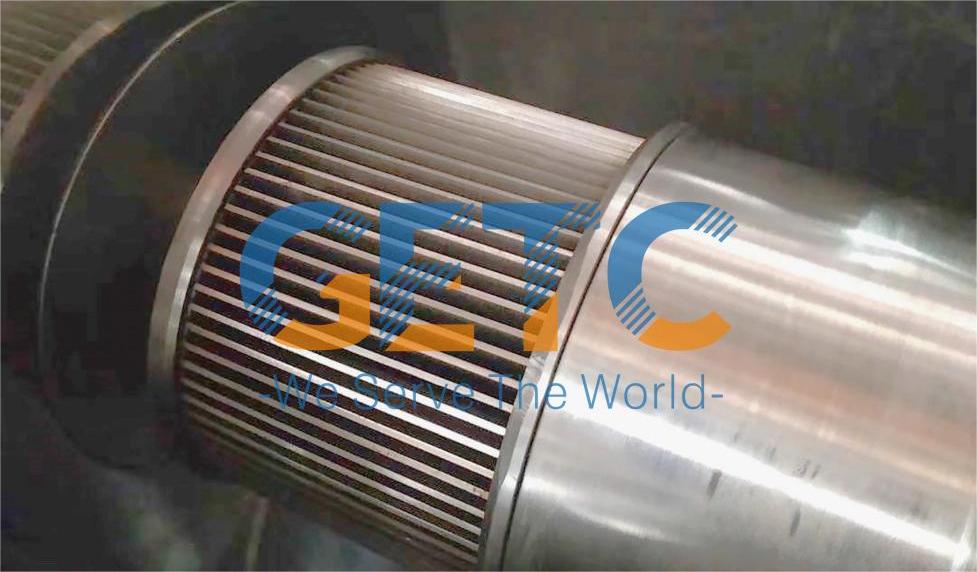

The agitation provided by the grinding chamber and nozzle design cause particles to become entrained in the air or inert gas stream. Particle size reduction is accomplished by high velocity collisions between particles. Small particles are then swept towards the classifier which rotates at high speed above the grinding. The speed of the classifier is preset for the proper sized product and is electronically controlled. Material which is fluidized fine enough to overcome the inertial force generated by the classifier escapes the jet mill and is collected as product. Oversized particles are recycled by the classifier back into the grinding chamber for further reduction.

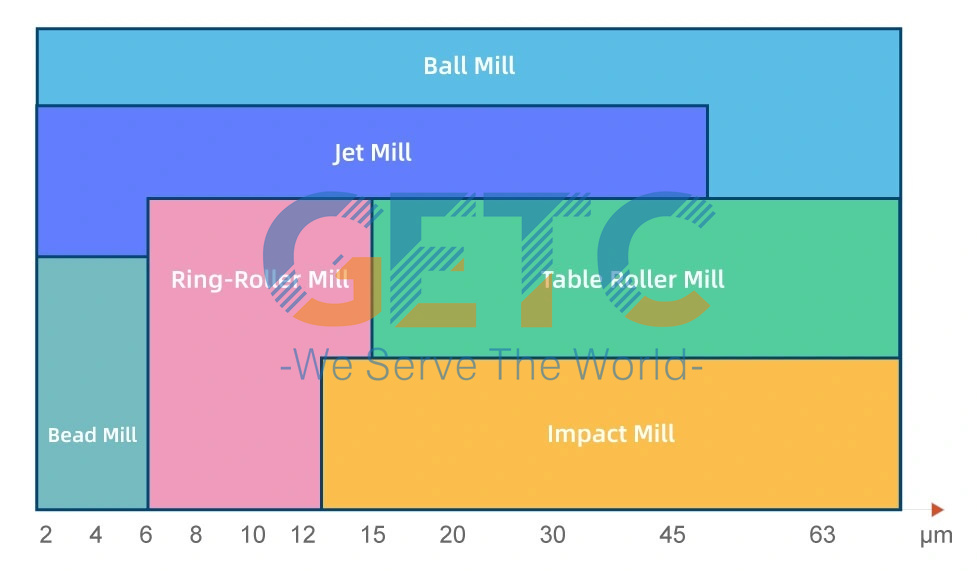

With the advanced design of the integrated, dynamic classifier, particle size distribution can be more easily controlled. Efficient use of compressed air and total system automation ensure manufactured product is of the highest quality. Capable of grinding dry powders to 0.5~45 micron averages with specific top size and/or bottom size requirements.

Features:

- • Classifier wheel arranged horizontally in the classifier top section• Laboratory up to Production Models• Cool and contamination-free grinding• Rapid cleaning and easy validation• low production loss• Top sizes as fine as D90 of 1 micron• Low noise (less than 75 dB)• Variable speed classifier wheel for precise classification• Feature a Ceramic, PU lining to different materials• Be used to grind heat-sensitive products with critical heat limitations• Suitable for Chemicals, Minerals, Pharmaceuticals & Food Products

- Application:

- • Heat-sensitive materials such as toner, resin, wax, fat, ion exchangers, plant protectors, dyestuffs and pigments.

- • Hard and abrasive materials such as silicon carbide, zircon sand, corundum, glass frits, aluminium oxide, metallic compounds.

- • Highly pure materials where the requirement is contamination-free processing such as fluorescent powders,silica gel,special metals,ceramic raw materials,pharmaceuticals.

- • High-performance magnetic materials based on rare earth metals such as neodymium-iron-boron and samarium-cobalt. Mineral raw materials such as kaolin, graphite, mica, talc.

- • Selectively ground composite materials such as metal alloys.

- SPEC:

Model | Air Consumption (m3/min) | Working Pressure (Mpa) | Target Size (micron) | Capacity (kg/h) | Installed Power (kw) |

DCF-50 | 1 | 0.7-0.85 | 0.5-30 | 0.5-3.0 | 8 |

DCF-100 | 2 | 0.7-0.85 | 0.5-30 | 3-10 | 16 |

DCF-150 | 3 | 0.7-0.85 | 0.5-30 | 10-150 | 40 |

DCF-250 | 6 | 0.7-0.85 | 0.5-30 | 50-200 | 60 |

DCF-400 | 10 | 0.7-0.85 | 0.5-30 | 100-300 | 95 |

DCF-600 | 20 | 0.7-0.85 | 0.5-30 | 200-500 | 180 |

Detail

|  |

|  |

|  |

|  |

At GETC, we pride ourselves on providing top-of-the-line Spiral Jet Mills that deliver exceptional performance in pharmaceutical and pesticide industries. Our innovative design and precision engineering ensure that particles are effectively entrained in the air or inert gas stream, resulting in superior product quality and efficiency. With years of experience and expertise in the field, we are dedicated to meeting the unique requirements of our customers and exceeding expectations. Choose GETC as your trusted Spiral Jet Mill supplier and experience the difference in milling technology.