High Efficiency Screw Feeding Mill rau Particle loj txo

DCF series dav hlau mills yog ib lub dav hlau dav hlau tshuab uas muaj cov yam ntxwv sib txawv ntawm qhov sib tsoo nozzles thiab cov khoom sib cais. Cua los yog inert roj ntawm siab siab yog txhaj los ntawm tshwj xeeb tsim nozzles ncaj qha mus rau hauv lub sib tsoo chamber ntawm lub zeb, tsim ib tug sonic los yog supersonic sib tsoo kwj. Raw pub yog cia li nkag mus rau lub zeb chamber los ntawm ib tug interlocked pub tswj system.

- Lus Taw Qhia:

Kev ntxhov siab muab los ntawm kev sib tsoo chamber thiab nozzle tsim ua rau cov khoom ua kom nkag mus rau hauv cov huab cua lossis inert gas kwj. Kev txo qhov loj me me yog ua tiav los ntawm kev sib tsoo nrawm ntawm cov khoom. Cov khoom me me yog ces swept mus rau lub classifier uas rotates ntawm kev kub ceev saum kev sib tsoo. Qhov ceev ntawm lub classifier yog preset rau cov khoom tsim nyog thiab yog hluav taws xob tswj. Cov khoom uas yog fluidized zoo txaus los kov yeej lub inertial quab yuam generated los ntawm cov classifier dim lub dav hlau zeb thiab yog sau raws li cov khoom. Cov khoom loj loj yog rov ua dua los ntawm cov khoom faib rov qab mus rau hauv kev sib tsoo chamber kom txo qis ntxiv.

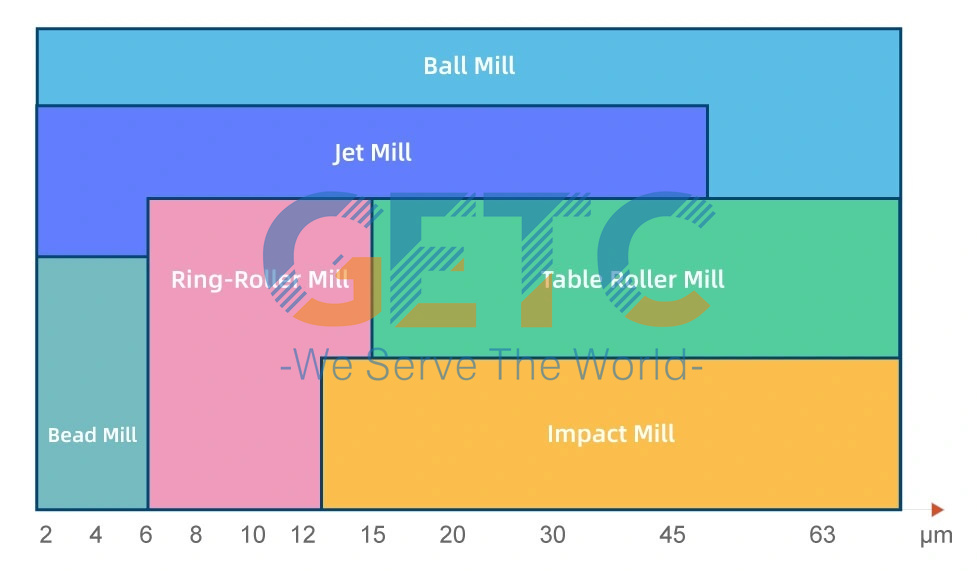

Nrog rau kev tsim kho siab tshaj plaws ntawm kev sib xyaw ua ke, cov khoom lag luam dynamic, particle loj tis tuaj yeem tswj tau yooj yim dua. Kev siv tau zoo ntawm cov cua compressed thiab tag nrho cov tshuab automation xyuas kom cov khoom tsim khoom yog qhov zoo tshaj plaws. Muaj peev xwm sib tsoo cov hmoov qhuav rau 0.5 ~ 45 micron qhov nruab nrab nrog rau qhov loj me thiab / lossis hauv qab qhov xav tau.

Nta:

- • Classifier log teem horizontally nyob rau hauv lub classifier sab saum toj seem • Laboratory mus txog ntau lawm Model • Txias thiab tsis muaj kab mob sib tsoo • ceev ceev thiab yooj yim validation • tsawg ntau lawm poob • Sab saum toj loj npaum li cas zoo li D90 ntawm 1 micron • Tsawg suab nrov (tsawg dua 75 dB) • Lub log sib txawv ceev ceev rau cov kev faib tawm meej • Muab cov Ceramic, PU hauv ob sab phlu rau cov khoom sib txawv • Siv los zom cov khoom kub-rhiab heev nrog cov kev txwv kub tseem ceeb • Haum rau cov tshuaj, Minerals, Pharmaceuticals & Khoom noj khoom haus

- Daim ntawv thov:

- • Thaum tshav kub kub-rhiab cov ntaub ntawv xws li toner, resin, ciab, roj, ion exchangers, nroj tsuag tiv thaiv, dyestuffs thiab pigments.

- • Cov ntaub ntawv tawv thiab abrasive xws li silicon carbide, zircon xuab zeb, corundum, iav frits, aluminium oxide, metallic compounds.

- • Cov ntaub ntawv ntshiab heev uas qhov yuav tsum tau ua yog tsis muaj paug xws li fluorescent hmoov, silica gel, tshwj xeeb hlau, ceramic raw khoom, tshuaj.

- • Cov khoom siv hlau nplaum ua tau zoo raws li cov hlau tsis tshua muaj hauv ntiaj teb xws li

neodymium-hlau-boron thiab samarium-cobalt. Mineral raw khoom xws li kaolin, graphite, mica, talc.

- • Xaiv cov khoom siv hauv av xws li cov hlau alloys.

- SPEC:

Qauv | Kev siv cua (m3/ min) | Ua haujlwm siab (Mpa) | Lub hom phiaj loj (micron) | Peev xwm (kg / h) | Lub zog hluav taws xob (kw) |

DCF-50 | 1 | 0.7-0.85 Nws | 0.5-30 | 0.5-3.0 | 8 |

DCF-100 | 2 | 0.7-0.85 Nws | 0.5-30 | 3-10 | 16 |

TXF-150 | 3 | 0.7-0.85 Nws | 0.5-30 | 10-150 | 40 |

TXF-250 | 6 | 0.7-0.85 Nws | 0.5-30 | 50-200 | 60 |

TXF-400 | 10 | 0.7-0.85 Nws | 0.5-30 | 100-300 | 95 |

TXF-600 | 20 | 0.7-0.85 Nws | 0.5-30 | 200-500 | 180 |

Paub meej

|  |

|  |

|  |

|  |

Txhim kho koj cov txheej txheem txo qhov me me nrog peb cov ntsia hlau noj Mills. Kev tsim kho tshiab ntawm cov cuab yeej no ua kom pom kev ua haujlwm zoo, tso cai rau kev tswj xyuas meej ntawm qhov loj me me. Lub tshuab thev naus laus zis tom qab peb lub zeb ua kom muaj kev sib koom ua ke rau hauv ntau qhov kev lag luam, muab ntau yam kev daws teeb meem rau koj cov kev xav tau ua. Hais goodbye rau inefficiencies thiab nyob zoo rau cov txiaj ntsig zoo nrog peb Cov Ntsia Hlau Pub Mill.