Hammer Mill ea boleng bo holimo bakeng sa Meriana/ Likokoana-hloko - GETC

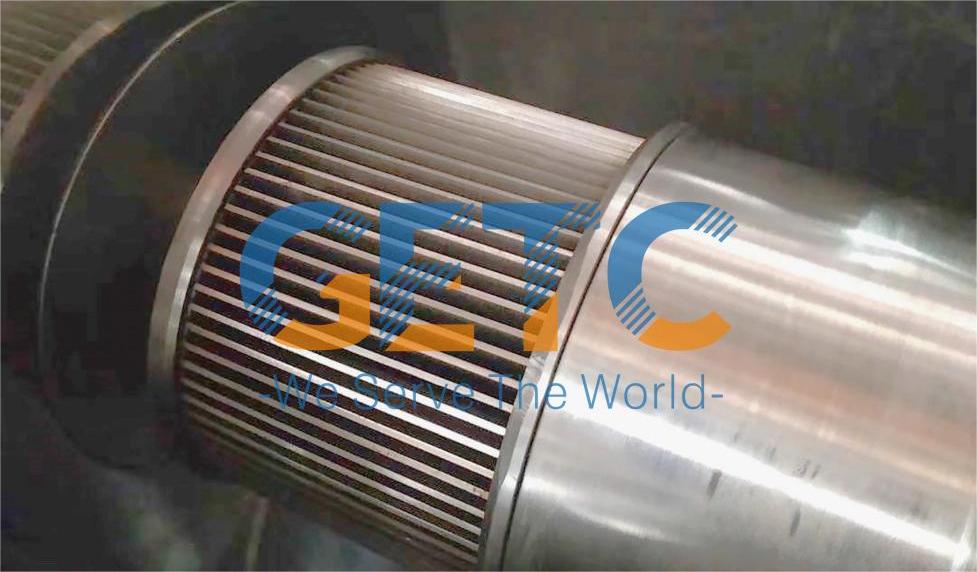

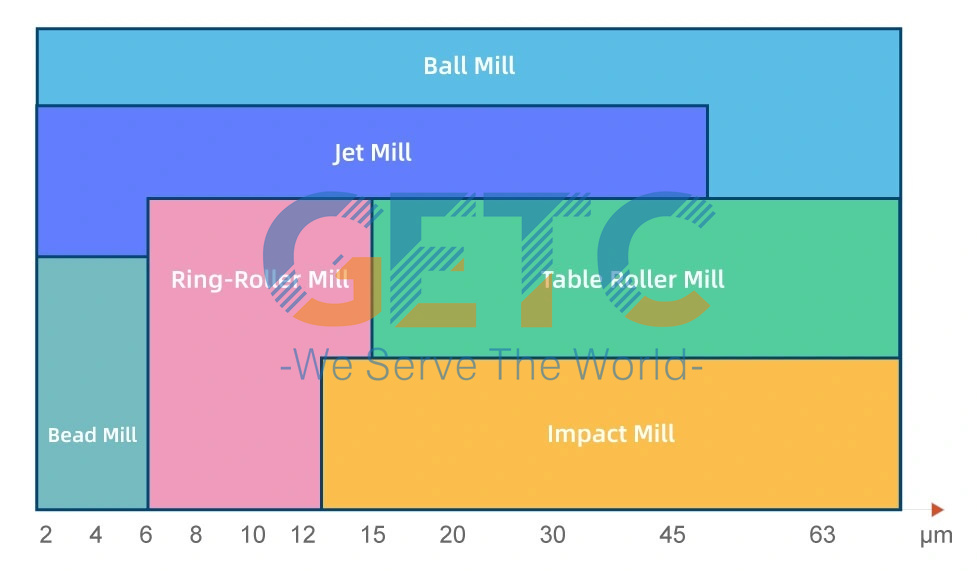

DCF series jet mill ke leloala la jet la mokelikeli le nang le li-nozzles tse hanyetsanang le sehlopha se matla. Moea kapa khase e se nang moea ka khatello e phahameng e kenngoa ka li-nozzles tse entsoeng ka mokhoa o khethehileng ka ho toba ka phaposing ea ho sila ea leloala, 'me ho etsa hore ho be le molapo o silang oa sonic kapa supersonic. Lijo tse tala li hlahisoa ka mokhoa o ikemetseng kamoreng ea ho sila ka mokhoa o hokahaneng oa taolo ea phepelo.

- Kenyelletso e Khutšoanyane:

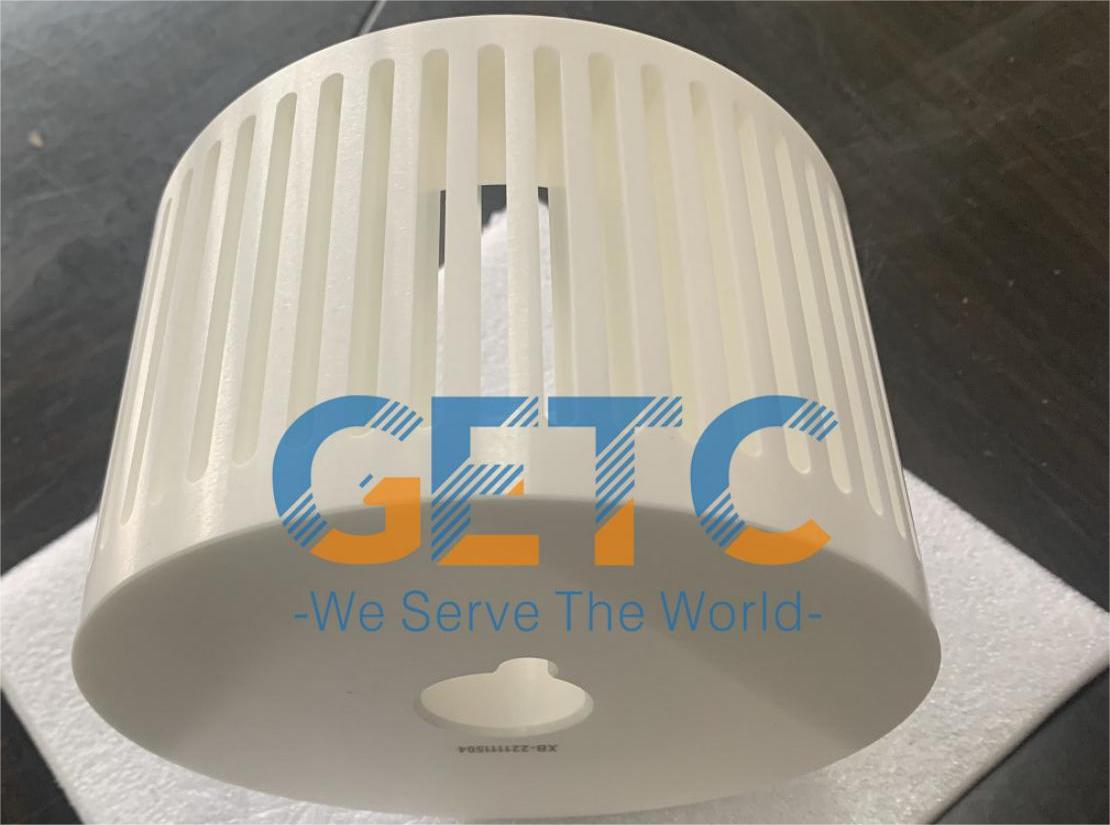

Likaroloana:

- • Lebili la Classifier le hlophisitsoe ka mokhoa o otlolohileng karolong e ka holimo ea sehlopha sa lihlopha• Laboratori ho fihla ho Mefuta ea Tlhahiso• Ho sila ho phodileng le ho sa silafatsoang• Ho hloekisa ka potlako le ho netefatsa habonolo• Tahlehelo e tlase ea tlhahiso• Mekhabiso e holimo e lekana le D90 ea 1 micron• Lerata le tlase (ka tlase ho 75 dB)• Lebili le feto-fetohang la maemo a lebelo bakeng sa ho hlophisoa hantle• E fana ka Ceramic, PU line ho lisebelisoa tse fapaneng• E sebelisoa ho sila lihlahisoa tse sa utloeng mocheso le mocheso o fokolang haholo• E loketse lik'hemik'hale, liminerale, meriana le lihlahisoa tsa lijo.

- Kopo:

- • Lisebelisuoa tse thibelang mocheso tse kang toner, resin, boka, mafura, li-ion, li sireletsang limela, dae le mebala.

- • Lisebelisoa tse thata le tse senyang tse kang silicon carbide, lehlabathe la zircon, corundum, likhalase tsa khalase, aluminium oxide, metsoako ea tšepe.

- • Lisebelisuoa tse hloekileng haholo moo tlhokahalo e leng ho sebetsa ntle le tšilafalo joalo ka phofshoana ea fluorescent, gel ea silica, tšepe e khethehileng, lisebelisoa tse tala tsa ceramic, meriana.

- • Lisebelisoa tse phahameng tsa makenete tse thehiloeng holim'a litšepe tse sa tloaelehang tsa lefatše tse kang neodymium-iron-boron le samarium-cobalt. Lisebelisoa tse tala tsa liminerale tse kang kaolin, graphite, mica, talc.

- • Lisebelisuoa tse kopantsoeng ka mokhoa o ikhethileng tse kang li-alloys tsa tšepe.

- SPEC:

Mohlala | Tšebeliso ea Moea (m3/mets) | Khatello ea ho sebetsa (Mpa) | Boholo ba sepheo (micron) | Bokhoni (kg/h) | Matla a kentsoeng (kw) |

DCF-50 | 1 | 0.7-0.85 | 0.5-30 | 0.5-3.0 | 8 |

DCF-100 | 2 | 0.7-0.85 | 0.5-30 | 3-10 | 16 |

DCF-150 | 3 | 0.7-0.85 | 0.5-30 | 10-150 | 40 |

DCF-250 | 6 | 0.7-0.85 | 0.5-30 | 50-200 | 60 |

DCF-400 | 10 | 0.7-0.85 | 0.5-30 | 100-300 | 95 |

DCF-600 | 20 | 0.7-0.85 | 0.5-30 | 200-500 | 180 |

Lintlha

|  |

|  |

|  |

|  |

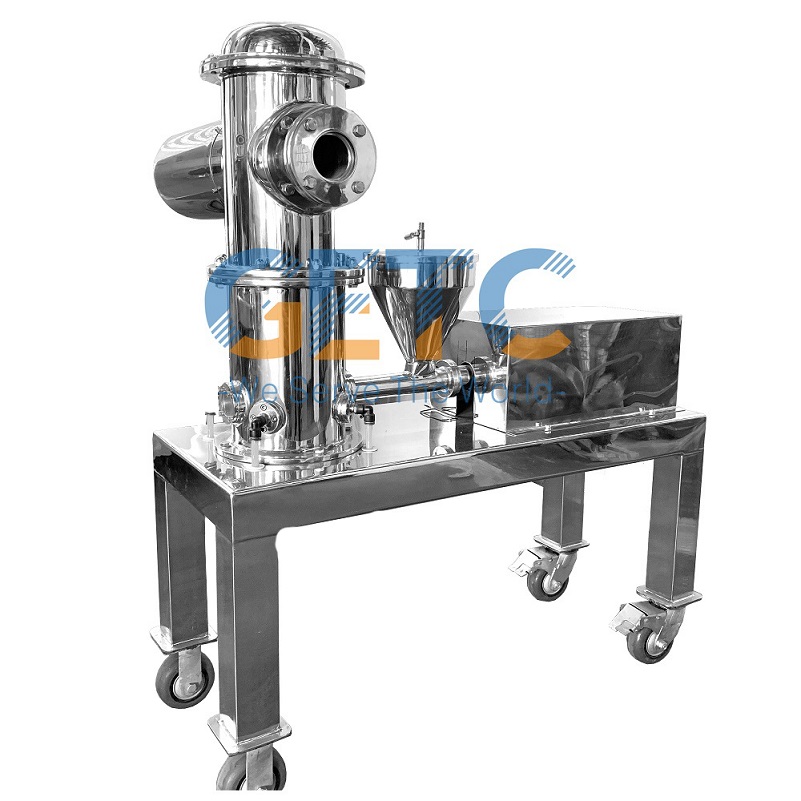

Ho GETC, re motlotlo ho fana ka leloala la rona la holimo-limo la Hammer, le etselitsoeng litlhare le chefo e bolaeang likokoanyana ka ho khetheha. Moqapi o ikhethang oa thepa ea rona o lumella mokhoa o laoloang le o nepahetseng oa ho sila, ho etsa bonnete ba hore likaroloana li arolelitsoe ka ho lekana le boholo bo lumellana. Ka bokhoni ba ho iketsetsa litlhophiso le li-parameter, leloala la rona la Hammer le fana ka phetoho e ke keng ea lekanngoa le ho nepahala ha ho hlahisa li-powders tse ntle bakeng sa mefuta e fapaneng ea liindasteri. Theknoloji ea rona ea morao-rao e kopanya tšusumetso ea lebelo le phahameng le ho arola moea ho finyella kabo e lakatsehang ea boholo ba likaroloana, e leng se hlahisang lihlahisoa tsa boleng bo phahameng ba ho qetela. Ho sebetsa hantle ha leloala la Hammer ho fokotsa tšebeliso ea matla le ho fokotsa litšila, ho e etsa tharollo e bolokang chelete e ngata bakeng sa litlhoko tsa hau tsa ts'ebetso. Tšepa GETC ho fana ka lisebelisoa tse tšepahalang le tse sebetsang hantle tsa Hammer bakeng sa litlhoko tsohle tsa hau tsa tlhahiso ea meriana le chefo.