Mofani oa Tsamaiso ea Tsamaiso ea Phatlalatso ea Khase ea Nitrogen e Phahameng ka ho Fetisisa - GETC

Leloala la pin ( leloala la pin, micro pin mill, fine pin mill, pin mill grinding, pin mill Crush, pin mill pulverizer, pin grinding equipment) ke mochini oa ho sila o tsamaisang thepa ka ts'ebetso ea likhoele tse tsamaeang khafetsa. . Joalo ka kichineng blender, e pshatla lintho ka tšusumetso e pheta-phetoang.

- Kenyelletso e Khutšoanyane:

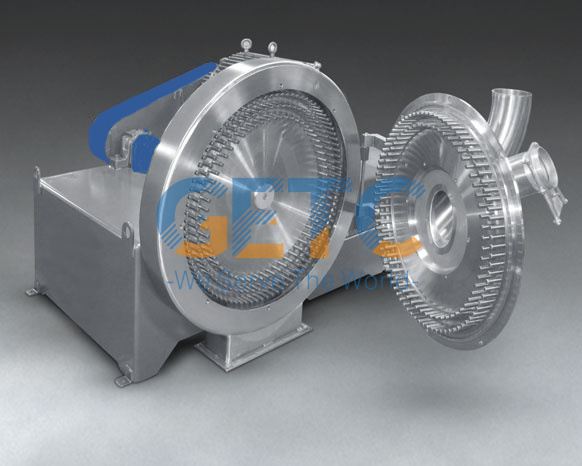

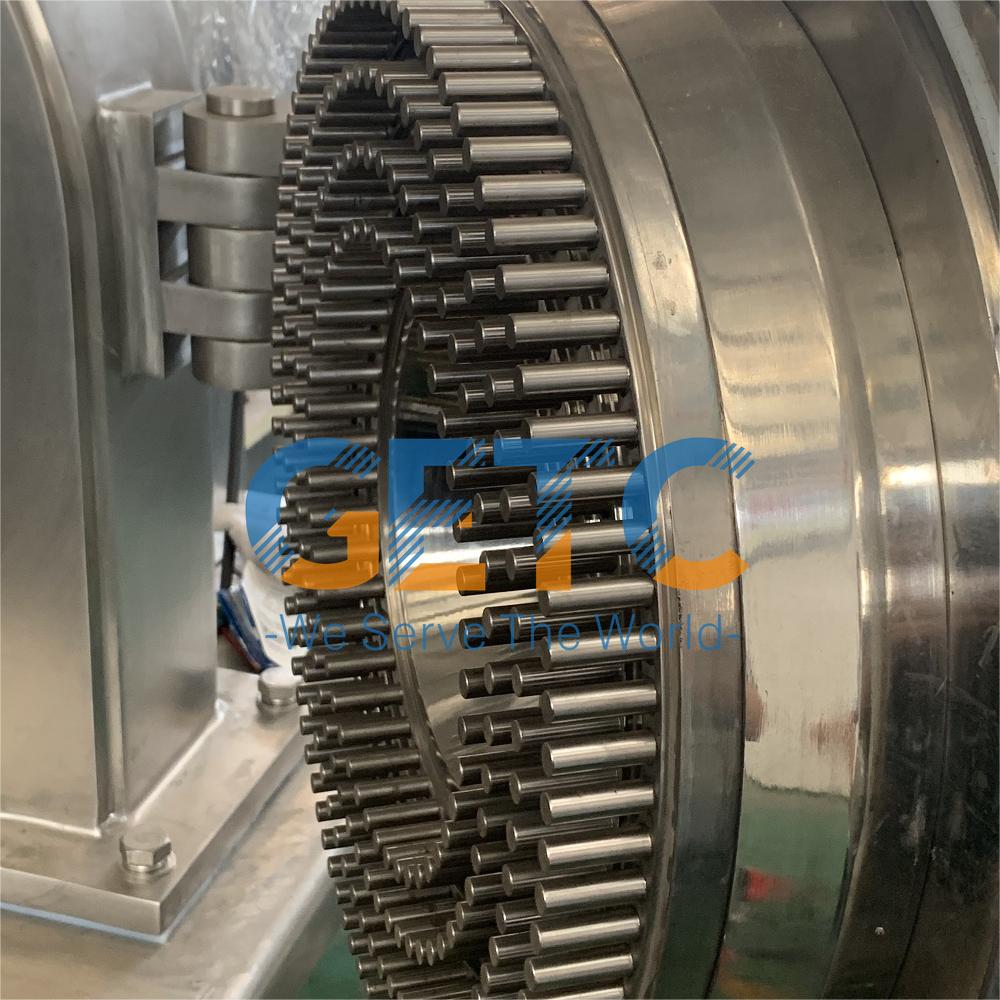

Leloala ke mofuta oa leloala la vertical shaft impactor mme le na le li-discs tse peli tse bilikang tse nang le lithakhisa tse kentsoeng sefahlehong se le seng.

Li-discs li hlophisitsoe ka tsela e bapileng e le hore lithakhisa tsa disk e 'ngoe li shebane le tse ling. Ntho e lokelang ho etsoa homogenized e fepeloa sebakeng se lipakeng tsa li-disk mme disk e le 'ngoe kapa ka bobeli li fetotsoe ka lebelo le phahameng.

Litsila tsa phini li ka sebelisoa linthong tse omeletseng le linthong tse emisitsoeng tsa metsi.

meriana, kaha li ka finyella boholo ba likaroloana tse ka tlaase ho li-micrometer tse seng kae.

Boitsebiso bo kenngoa ka mokhoa o ts'oanang ka kamoreng ea ho sila ka mokhoa oa ho fepa, o anngoeng ka matla ke disk e potolohang ka lebelo le phahameng.

Ka nako e ts'oanang, e tlas'a matla a fapaneng a fapaneng a kang khohlano, ho kuta le ho thulana pakeng tsa static disc le ring gear ho sila thepa.

Diski e tsamaeang le static disc e ka kopanngoa ka mefuta e fapaneng ea meralo ho latela tlhaho ea thepa ho fihlela litlhoko tsa ho sila tsa lisebelisoa tse fapaneng.

Likaroloana:

- • E fumaneha D50:10-45μm.

• Ha ho sieve, ho lahla hamonate, bokhoni bo phahameng le litšenyehelo tse tlaase tsa ts'ebetso.

• Lebelo le phahameng la mohala, boholo bo fokolang ba phatsa.

• Sebopeho se kopaneng le mosebetsi o monyane. bonolo ho qhaqholla le ho hlwekisa

• Matla a tlase a ho kenya, ts'ebeliso e pharaletseng, ts'ebetso e phahameng ea litšenyehelo.

• Metsoako e fapaneng ea ho kenya, e sebetsang litlhoko tse fapaneng tsa ts'ebetso

• Ho sila ho ka har'a tsamaiso e koetsoeng, lerōle le tlaase le lerata, ts'ebetso ea tlhahiso e hloekileng le e sireletsang tikoloho.

• Sistimi ea taolo ea PLC, ts'ebetso e bonolo.

• Koloi e le 'ngoe kapa habeli, haeba e ntlafalitsoe ho ea ho matla a mabeli, a fihlang ho 200m/s kapa ho feta lebelo la mohala, ho fumana matla a holimo a ho sila.

• Enjene e ka kopanngoa le lebanta ho eketsa lebelo le ho phunyeletsa bothata ba li-motor tse lebelo le holimo ntle le mochine o tsebahalang oa motlakase.

• E ka sebelisoa ka lihlopha tse nang le lihlopha tsa mekhahlelo e mengata ho hlahisa lihlahisoa tse nang le boholo bo bongata ka nako e le 'ngoe.

• Moralo oa boikhethelo o thibelang ho phatloha, o fihlela litlhoko tsa ho sila ka mokhoa o hlakileng oa oxide e ka tukang le e phatlohang.

lisebelisoa

• Mocheso o phahameng, mocheso o tlase, mocheso o tloaelehileng, potoloho e thibelang moea, meralo ea potoloho ea khase e Inert e teng, bakeng sa mefuta e fapaneng.

ditlhoko tsa ho sila tsa disebediswa tse fapaneng.

- Kopo:

E sebelisoa haholo lik'hemik'hale, letsoai la inorganic, meriana, lijo, li-pigments, dae, chefo e bolaeang likokoanyana, lisebelisoa tsa betri, liminerale, lisebelisoa tsa refractory le liindasteri tse ling.

- SPEC:

Mohlala | DPM160 | DPM260 | DPM400 | DPM510 |

Matla a Matla a Matla (kw) | 4 | 11 | 22 | 37 |

Daela Max Speed (rpm) | 24000 | 16000 | 12000 | 9000 |

Palo ea Mela ea ho Daela | 3 | 3 | 3 | 3 |

Size ea Sekhahla sa Prushing D97 (um) | 10-500 | 10-500 | 10-500 | 10-500 |

Lintlha

|  |

|  |

Ho GETC, re motlotlo ho ba barekisi ba ka sehloohong ba Nitrogen Gas Circulation Milling Systems. Theknoloji ea rona ea maemo a holimo le moralo o mocha o fana ka nepo le bokhabane bo ke keng ba lekanngoa ts'ebetsong ea ho sila. Sistimi e na le leloala le otlolohileng la shaft e nang le li-disc tse peli tse bilikang, e 'ngoe le e' ngoe e kentsoeng ka lithakhisa tsa boleng bo holimo bakeng sa ts'ebetso e phahameng. Ka Sistimi ea rona ea Nitrogen Circulation Milling System, o ka fihlela kabo e ntle ea boholo ba likaroloana le boleng bo tsitsitseng ba sehlahisoa bakeng sa lits'ebetso tse fapaneng. Tšepa GETC bakeng sa litharollo tse tšepahalang, tse sebetsang hantle haholo tse etselitsoeng ho fihlela litlhoko tsa hau tse ikhethileng.