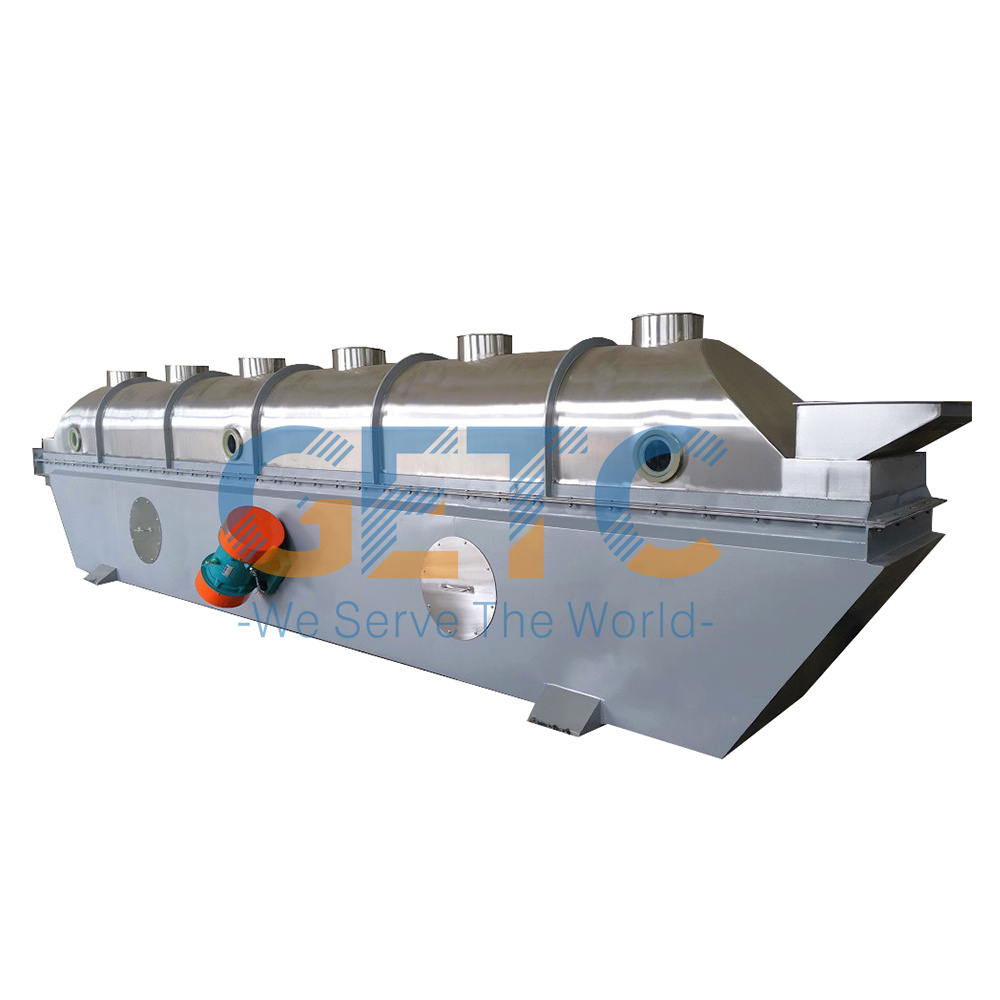

Superior Fluidized Granulating Dryer from GETC

Industrial continuous horizontal vibration fluid bed dryer is made by vibrating motor to produce excitation force to make the machine vibrate, the material jumps forward under the action of this excitation force in the given direction, while the hot air is input at the bottom of the bed to make the material in fluidized state, the material particles are in full contact with the hot air and carry out intense heat and mass transfer process, at this time the highest thermal efficiency. The upper cavity is in the state of micro-negative pressure, the wet air is led out by the induced fan, and the dry material is discharged from the discharge port, so as to achieve the ideal drying effect.

Product Description:

- Industrial continuous horizontal vibration fluid bed dryer is made by vibrating motor to produce excitation force to make the machine vibrate, the material jumps forward under the action of this excitation force in the given direction, while the hot air is input at the bottom of the bed to make the material in fluidized state, the material particles are in full contact with the hot air and carry out intense heat and mass transfer process, at this time the highest thermal efficiency. The upper cavity is in the state of micro-negative pressure, the wet air is led out by the induced fan, and the dry material is discharged from the discharge port, so as to achieve the ideal drying effect. If cold air or wet air is sent to the bottom of the bed, it can achieve cooling and humidifying effect.

Feature:

- •Vibrating source is driven by vibrating motor, with smooth operation, easy maintenance, low noise, long service life and convenient maintenance.

•High thermal efficiency, can save more than 30% energy than general drying device. Uniform bed temperature distribution, no local overheating.

• Good adjustability and wide adaptability. The thickness of the material layer and the speed of moving as well as the change of the whole amplitude can be adjusted.

• It can be used for drying fragile material because of the small damage to the material surface.

• The fully enclosed structure effectively prrotects the clean working environment.

• The mechanical efficiency and thermal efficiency are high, and the energy saving effect is good, which can save 30-60% energy than the general drying device.

Application:

- • The vibrating fluidized bed dryer is widely used for drying, cooling, humidifying and other operations of powder granular materials in chemical, light industry, medicine, food, plastic, grain and oil, slag, salt making, sugar and other industries.• Medicine and chemical industry: various pressed granules, boric acid, benzene diol, malic acid, maleic acid,pesticide WDG, etc.

• Food building materials: chicken essence,lees, monosodium glutamate, sugar, table salt, slag, bean paste, seeds.

• It can also be used for the cooling and humidification of materials, etc.

Specification:

Model | Area Of Fluidized-Bed (M3) | Temperature Of Inlet Air (℃) | Temperature Of Outlet Air (℃) | Capacity Of Vapor Moisture (kg/h) | Vibration Motor | |

Model | Powder (kw) | |||||

ZLG-3×0.30 | 0.9 |

70-140 |

70-140 | 20-35 | ZDS31-6 | 0.8×2 |

ZLG-4.5×0.30 | 1.35 | 35-50 | ZDS31-6 | 0.8×2 | ||

ZLG-4.5×0.45 | 2.025 | 50-70 | ZDS32-6 | 1.1×2 | ||

ZLG-4.5×0.60 | 2.7 | 70-90 | ZDS32-6 | 1.1×2 | ||

ZLG-6×0.45 | 2.7 | 80-100 | ZDS41-6 | 1.5×2 | ||

ZLG-6×0.60 | 3.6 | 100-130 | ZDS41-6 | 1.5×2 | ||

ZLG-6×0.75 | 4.5 | 120-170 | ZDS42-6 | 2.2×2 | ||

ZLG-6×0.9 | 5.4 | 140-170 | ZDS42-6 | 2.2×2 | ||

ZLG-7.5×0.6 | 4.5 | 130-150 | ZDS42-6 | 2.2×2 | ||

ZLG-7.5×0.75 | 5.625 | 150-180 | ZDS51-6 | 3.0×2 | ||

ZLG-7.5×0.9 | 6.75 | 160-210 | ZDS51-6 | 3.0×2 | ||

ZLG-7.5×1.2 | 9.0 | 200-260 | ZDS51-6 | 3.7×2 | ||

Detail:

|  |

|  |

|  |

Our horizontal vibration fluid bed dryer is designed for maximum performance, utilizing vibrating motors to create excitation force that drives material forward in a fluidized state. With hot air input at the base, the material undergoes intense heat and mass transfer processes, ensuring the highest thermal efficiency. Trust GETC for a reliable and efficient granulating dryer solution for your industrial needs.