Top Supplier of Ceramic Liner Jet Mill - GETC

A pin mill (pin mill grinding,micro pin mill,fine pin mill,pin mill grinding, pin mill Crush, pin mill pulverizer,pin grinding equipment) is a mill machine that comminutes materials by the action of pins that repeatedly move past each other. Much like a kitchen blender, it breaks up substances through repeated impact.

- Brief Introduction:

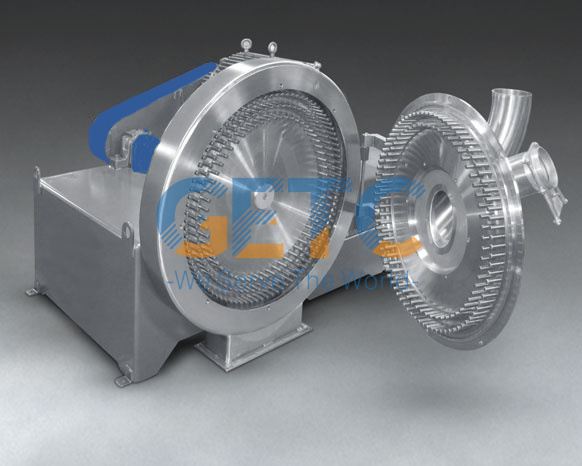

The mill is a type of vertical shaft impactor mill and consists of two rotating discs with pins embedded on one face.

The discs are arrayed parallel to each other so that the pins of one disk face those of the other. The substance to be homogenized is fed into the space between the disks and either one or both disks are rotated at high speeds.

Pin mills can be used on both dry substances and liquid suspensions.Pin mills are commonly use in the manufacture of

pharmaceuticals, as they can achieve particle sizes as low as a few micrometers.

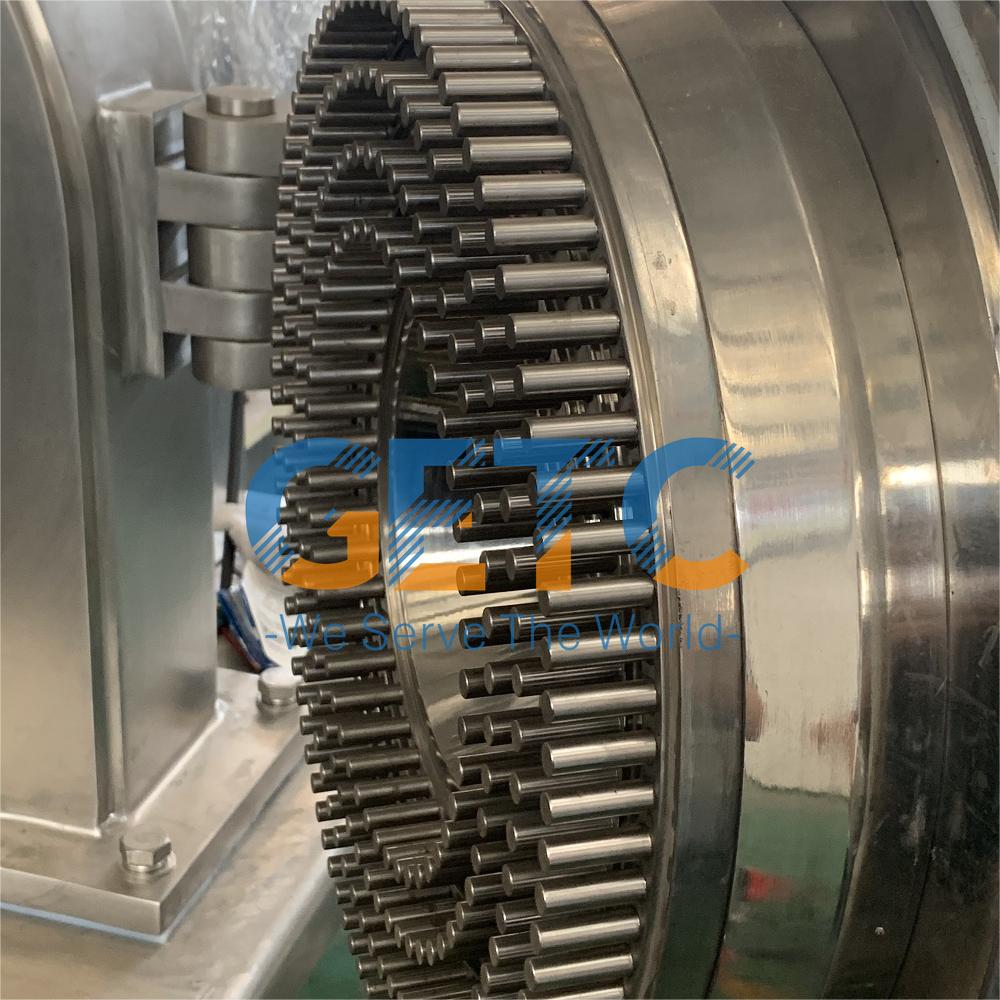

The material is evenly fed into the grinding chamber by the feeding system, strongly impacted by the high-speed rotating disc.

At the same time, it is subjected to various comprehensive forces such as friction, shearing and collision between the static disc and the ring gear to grind material.

The moving disc and static disc can be combined in different structural forms according to nature of material to meet the grinding requirements of different materials.

Features:

- • Available D50:10-45μm.

• No sieve, smooth discharge, high capacity and low operation cost.

• High line speed, finer particle size.

• Compact structure and small occupation. easy to disassemble and clean

• Lower installation power, wide application, high cost-performance.

• Different installation combinations, applicable to different process requirements

• Grinding is in closed system, low dust and noise, clean and environmentally friendly production process.

• PLC control system, easy operation.

• Single or double drive, if upgraded to dual power, reaching 200m/s or more line speed, to obtain the maximum grinding force

• The motor can be connected with a belt to increase the speed and break through the problem of high-speed motors without the well-known motor brand.

• Can be used in series with multi-stage classifiers to produce products with multiple sizes at one time.

• Optional explosion-proof design, meet the ultra-fine grinding processing requirements of flammable and explosive oxide

materials

• High-temperature, low-temperature, normal-temperature, airtight cycle, Inert gas cycle designs are available, for different

grinding requirements of different materials.

- Application:

Widely used in chemical, inorganic salt, medicine, food, pigments, dyes, pesticides, battery materials, minerals, refractory materials and other industries.

- SPEC:

Model | DPM160 | DPM260 | DPM400 | DPM510 |

Max Power Of Motor (kw) | 4 | 11 | 22 | 37 |

Dial Max Speed (rpm) | 24000 | 16000 | 12000 | 9000 |

Number of Dial Rows | 3 | 3 | 3 | 3 |

Crushing Particle Size D97 (um) | 10-500 | 10-500 | 10-500 | 10-500 |

Detail

|  |

|  |

Looking for a reliable supplier of Ceramic Liner Jet Mills? Look no further than GETC. Our innovative design features a vertical shaft impactor mill with two rotating discs embedded with high-quality pins for superior performance. Whether you're in the pharmaceutical, chemical, or food industry, our Ceramic Liner Jet Mill guarantees precise and efficient milling operations. With a reputation for excellence and a commitment to customer satisfaction, GETC is your go-to source for high-quality milling solutions. Trust us for all your milling needs and experience the difference in quality and performance with our Ceramic Liner Jet Mill.